Production Equipment Engineering

Production Equipment Engineering

Steuratech is not a global player – but part of your team.

Is your project too small for the large players in special-purpose machinery? For us, it’s exactly the right size. We focus entirely on small, custom automations, fixtures, and gauges that enable major improvements in your manufacturing processes. Small does not mean less complex. We provide precise, efficient engineering and commission the solutions together with you.

Your project matters. To you and to us.

Our Services

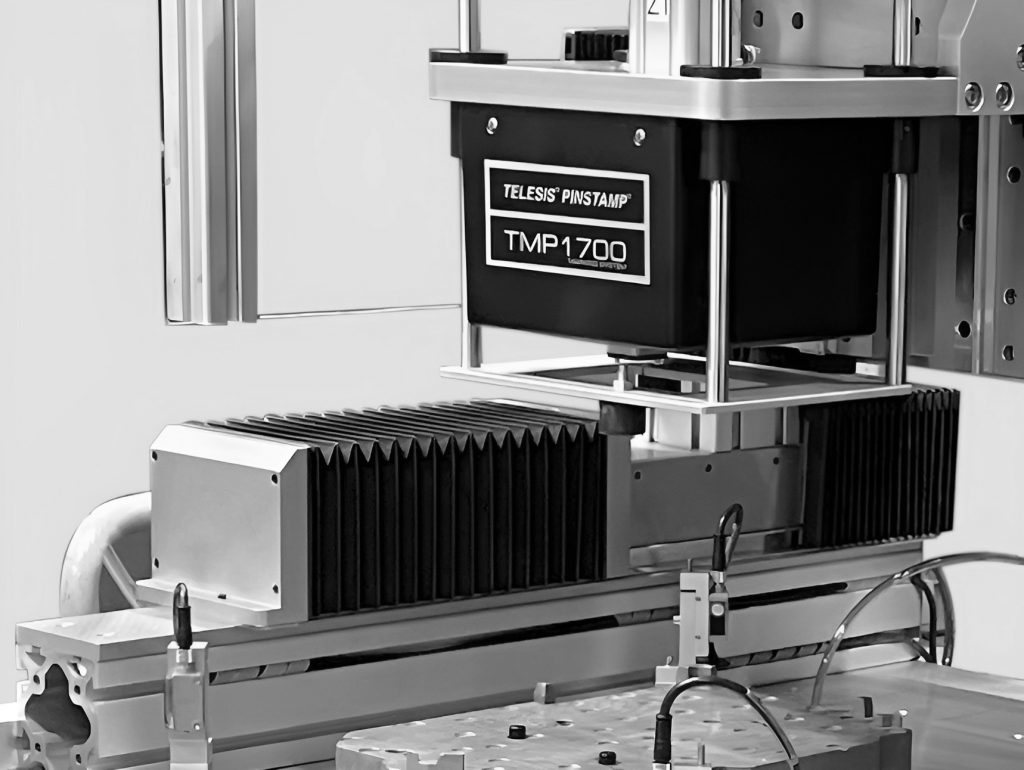

Automation:

Automating manufacturing processes can be complex and expensive. But it doesn’t have to be. We specialize in closing the gaps in your production that large special-purpose machine builders prefer to avoid. If your solution is available as an off-the-shelf product, you should buy it. If your solution costs more than €200,000, you should work with a large special-purpose machinery manufacturer. For everything in between, we are your partner.

Assembly Fixtures:

Many assembly tasks do not require or justify full automation. Take advantage of manual fixtures or semi-automated solutions to significantly improve your production. The single-part feeding of components increases efficiency. The correctly oriented and positioned part provisioning improves quality. We provide full engineering support for the small step that makes the difference.

Testing Fixtures:

Sometimes it’s worth knowing at exactly what torque a safety clutch actually disengages, or at what axial force a pin begins to slip. If you currently measure viscosity, coating thickness, solid objects, or similar properties using manual devices, we are happy to integrate these measurements fully or semi-automatically into your process chain.

Clamping Fixtures:

Whether for machining operations, clamping sheet metal parts in a welding cell, or repeatable, accurate fixturing of components in a measuring machine – the right clamping fixture is the foundation of a good result. Whenever one or more components need to be securely clamped and precisely aligned, we are your first point of contact.

Workpiece Carriers and Component Holders:

Even the largest and most sophisticated transfer system, regardless of its technical basis, cannot operate without suitable workpiece carriers. The same often applies to robotic automation. What truly matters is how your components and workpieces are held. Modifying existing component holders is often the simplest and most cost-effective way to implement a product redesign in your production.

Inspection Gauges:

Our inspection gauges are individually tailored to your components and allow for fast and reliable verification of features. Position gauges, labyrinth gauges, wire gauges, inspection pins, contour gauges – we design according to your inspection requirements. Whether wire brackets, turbine blades, die-cast parts, or your specific component: with our inspection gauges, you can quickly and reliably determine whether everything fits.